Comparison of inverter and soft starter: Features and applications

Engines often have great energy needs to start and quickly reach top speed. Soft starter and inverter can both be used to reduce inrush current and limit torque to protect mechanical equipment, avoid factory voltage drop and prolong motor life by reducing starting current operation of high-power motors or engines that require continuous starting and stopping. So when to use inverter, when to use soft start?

What is soft start? How does the soft starter work?

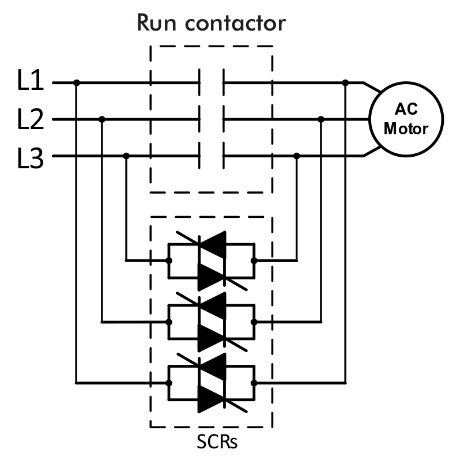

A soft starter is a device used to assist the starting process of an AC electric motor, which protects the motor from damage caused by sudden large currents when starting and avoids voltage drop in the power grid by gradually increase the voltage supplied to the motor from a predetermined voltage up to the rated voltage (for soft stop, vice versa).

Working principle of soft starter:

Soft start is commonly used in applications such as:

- Ask the engine to accelerate and increase torque slowly when starting or stopping the engine

- High starting current limiting for large motors to avoid problems with mains voltage drop or motor damage

- Start-up speed control to avoid sudden torque or tension damage to mechanical systems such as conveyors, belt drive systems, gears, couplings

- Apply pump motor to avoid sudden increase in pressure at the start of pump, causing water hammer to break the pipeline.

Benefits of a soft starter:

- Support start-up process, reduce grid voltage drop

- Motor protection in case of overcurrent, overvoltage, phase loss, input and output phase fault, underload, load short circuit protection, overload protection

- Increase engine life and mechanical components

What is an inverter? What are the benefits of starting with an inverter?

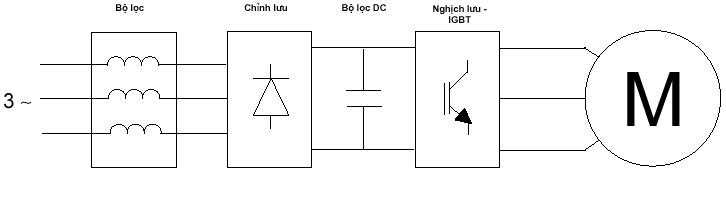

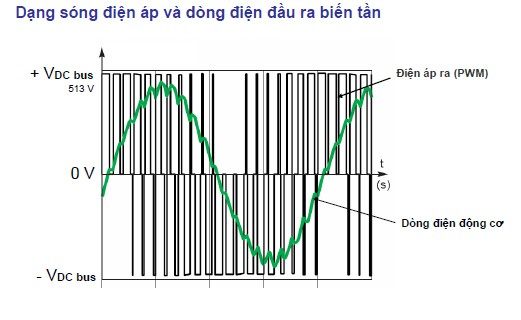

Inverter is a device that changes the frequency of the current applied to the coil inside the motor, thereby controlling the motor speed steplessly not only when starting the motor but also during the operation of the motor. device.

The 3-phase AC output system can change the amplitude and frequency values steplessly depending on the controller, thereby changing the motor speed as required during operation.

- Helps engine start smoothly, reducing mechanical wear

- Easily change the motor speed to meet the technological requirements of different equipment and systems

- Full range of motor protection functions such as overcurrent, overvoltage, phase loss, phase reversal, etc. to help increase motor life

- Efficiently save energy, protect equipment in the system

- Integrating various control functions to improve technology and increase production productivity

| Inverter | Soft start |

|---|---|

| It can change the motor speed flexibly, reverse the motor not only when starting and stopping the engine but also during the operation of the device. | Only accelerates or decelerates during starting and stopping the engine for “soft” starting or stopping, not reversing the motor. |

| Adjusting acceleration and deceleration time more flexible, wide adjustment range makes starting the engine extremely smooth | The adjustment range of the acceleration and deceleration time is narrow, starting is heavier, especially with large engines, the starting is quite difficult. |

| More protection functions for engines and mechanical systems | Few motor protection functions, only basic protection functions |

| It can start as many times a day and during the life of the equipment without affecting the engine and mechanical system. | Depending on engine capacity and factory, the number of starts may be limited |

| Changing the motor speed by frequency changes should not affect the starting torque | Changing the motor speed by changing the voltage should make the starting torque weak, need to pay attention to the load factor when choosing a soft starter |

| One inverter can be used for speed regulation and “soft stop” for multiple motors | A soft starter is used for a single engine only |

| Larger in size and takes up more space | More compact when compared to inverters of the same capacity |

| Higher price | Cheaper |

Related Posts

Preventive maintenance for inverter

What is an inverter, detailed structure of an inverter.