What are the main industrial applications of an inverter?

The introduction of AC Drives has dramatically increased factory productivity and contributed greatly to industrial development. By using AC Drives that can be easily converted into variable-speed drives, the advantages of “energy saving”, “soft start and soft stop”, “downsizing of power receiving equipment”, and “freely changing the direction of rotation” are realized. This section describes how these advantages of AC Drives are applied to various industrial applications.

Speed/Torque Controlled by Changing Frequency

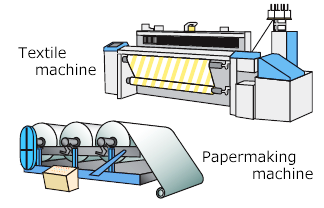

AC drives have been widespread since the 1970s, when they were first applied to textiles. The textile industry consists of a variety of processes, and the requirements for drives vary according to the application. Let’s have a look at one example about the winder control in the spinning process. The winder winds the stretched yarn using a roll, and it is necessary to control the tension and speed of the yarn bundle traveling at high speed. Paper machinery also has a winder and unwinder process, and the number of revolutions must be controlled according to the tension of the paper.

The inverter can easily change the motor speed and torque by changing the frequency, enabling highly accurate winder control. The wide speed control range is also suitable for textile and paper machinery that can operate at high speeds of tens of thousands of revolutions.

Energy Saving

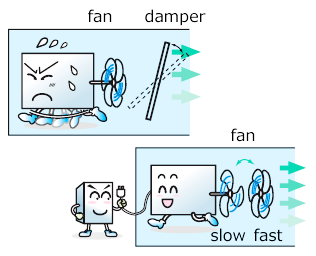

Energy saving can be realized by freely changing the rotation speed of the motor and not operating the machine more than necessary. In the case of fan blowers, for example, the air flow had to be adjusted by increasing or decreasing the air resistance with a damper (on-off valve). Even if the air volume is reduced, the amount of electricity used does not decrease so much. The same applies to pumps, where the flow rate is generally adjusted by valves. The drive motor runs at full capacity and consumes power. By using an AC drive, the air flow and flow rate can be adjusted by controlling the number of revolutions of the motor, thereby reducing the power consumption of the motor.

Compressors are attracting attention in recent years because of their large power consumption at plants and offices. By controlling the number of motor revolutions according to the amount of air used with AC drives, these compressors are highly effective in saving energy. In the case of constant output control, it can also contribute to higher machine efficiency by increasing the discharge air volume.

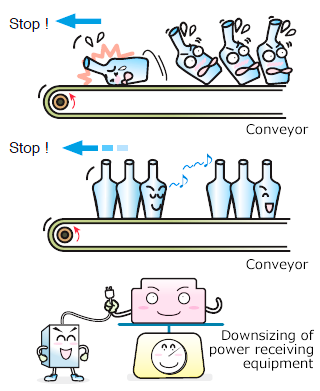

Soft Start and Soft Stop and Downsizing of Power Receiving Equipment

Since an AC Drive starts from a low frequency and the acceleration/deceleration can be set at any time, soft start/stop is possible. It helps prevent dropouts of loads on conveyors that move gently and change speed a lot. Also, by reducing the current at startup, the load on the power supply side is reduced and the power receiving equipment can be reduced.

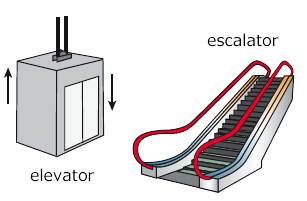

These features are ideal for elevators and escalators. Elevators that lift people need to move smoothly to improve basic performance such as ride comfort. In addition, space saving structures are required because they are often installed in limited building spaces.

Escalators are sometimes stopped by a human sensor when there is no one to save energy. However, if passengers get on and start moving suddenly, their body balance will be lost. If you use an AC drive, you can obtain safe acceleration by soft start.

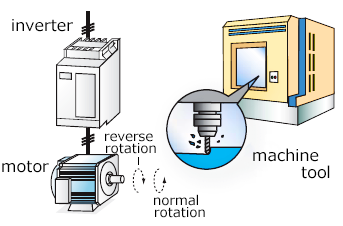

Change The Direction of Rotation Freely

The AC drive can easily change the direction of rotation simply by changing the internal input signal (rotation command). Also, unlike commercial power supplies, it does not apply a large starting current, and allows smooth acceleration and deceleration with a small current, enabling it to handle frequent start and stop operations. As well as the frequent lifting and lowering movements of elevators, the application merit is still outstanding in machine tools for processing metal workpieces.

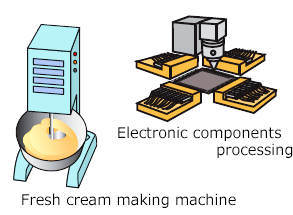

A typical example is a planer for machining a workpiece. Since the workpiece is cut by reciprocating linear motion, normal and reverse rotation are frequently performed. In addition, a wide range of variable speeds is required to obtain the optimum speed depending on the workpiece. Heavy cream, which is essential for making delicious cakes, can now be made by machine. The heavy cream machine programs the kneading movements of skilled craftsmen and controls the direction of rotation, number of revolutions and operating time with an inverter drive. The inverter ensures a stable production of high quality fresh cream.

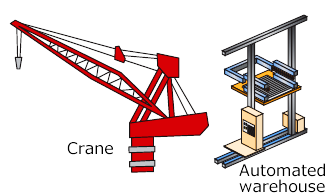

Further Energy Saving by Regenerative Electric Power

Stevedoring machines, such as cranes and automated warehouses, move things up and down, left and right, back and forth, and are extremely energy-changing machines. By combining the AC Drive with a regenerative system, the motor generates electric power – regenerative electric power- when the AC Drive is turned down. This makes it possible to achieve significant energy savings.

We have above introduced AC Drive solutions focusing on industrial applications. Responding to diverse demands for automation, speedup, and energy saving, these products are used not only in manufacturing but also in infrastructure related to society and daily life. The power conversion technology is also being applied to environmental energy such as electric vehicles, photovoltaic power generation, and wind and water power generation, and is expected to spread further.

Related Posts

Preventive maintenance for inverter

What is an inverter, detailed structure of an inverter.